The Machinist's Guide to Cylindrical Grinding and Superfinishing: What it Can Do and When to Outsource

In the competitive landscape of machining and metal part fabrication, machine shops are continually seeking ways to enhance their offerings, reduce lead times, and increase efficiency. While in-house machining capabilities lay the groundwork for shaping metal parts, achieving precision often requires specialized finishing processes like cylindrical grinding and superfinishing. There are many finishing options out there, but this guide is crafted for machinists and machine shop owners looking to broaden their expertise and make strategic decisions about cylindrical grinding and superfinishing services.

What are the Surface Finish and Tolerance Limits of Machining?

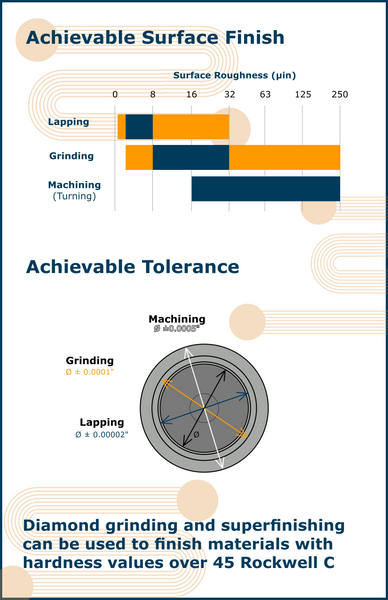

Machine shops excel in transforming raw materials into parts with basic geometries and tolerances. In-house machining operations like milling, turning, and drilling are fundamental, with achievable surface finishes ranging from 16 to 125 microinches (0.4 to 3.2 micrometers) and tolerances from ±0.005 inch to ±0.0005 inch. While these specifications meet a wide array of applications, certain high-precision components require even finer finishes and tighter tolerances.

What Surface Finish and Tolerance can Cylindrical Grinding Achieve?

Grinding elevates the surface finish and dimensional accuracy beyond what standard machining can offer, achieving finishes of 8 to 32 microinches (0.2 to 0.8 micrometers) and tolerances up to ±0.0001 inch. Some specialized grind shops also have diamond grinding capabilities that can finish surfaces with hardness over 45 Rockwell C (270 Vickers), including heat-treated parts and ones with ceramic or carbide coatings. Outsourcing grinding to specialists can provide machine shops with access to top-tier precision without the overhead of acquiring and maintaining advanced grinding machinery. This collaboration enables machine shops to offer finer finishes and tighter tolerances to their customers, enhancing their competitive edge.

What Surface Finish and Tolerance can Superfinishing Achieve?

Superfinishing takes surface finish a step further, capable of achieving finishes as fine as 0.5 microinches (0.012 micrometers) and tolerances as tight as ±0.00002 inch. This level of precision is essential for components in sealing environments such as hydraulic cylinders or piston rods. Given the niche nature and stringent requirements of superfinishing, outsourcing the process allows machine shops to provide their customers with the highest standards of surface quality without trying to master a new technique.

Strategic Benefits of Outsourcing Cylindrical Grinding and Superfinishing

- Quality and Precision: partnering with someone who specializes in precision grinding means your components are handled by experts who do this day in and day out.

- Save Time: free up your valuable, in-house resources and focus on your core manufacturing activities.

- Access to Advanced Technology: get the benefits of the latest in grinding technology without the hefty investment.

- Cost Efficiency: reduce your overhead costs associated with maintaining grinding equipment, training operators, and managing waste. Pay for what you need, when you need it, optimizing your operational budget.

- Flexibility and Scalability: whether you’re dealing with peak demand or unique, one-off projects, outsourcing offers the flexibility to scale your production up or down without the constraints of in-house capacity.

- Expand Your Offerings: with the support of outside precision grinding and superfinishing services, you can take on more diverse and complex projects, broadening your market reach and customer base.

Working Together to Help Machine Shops Excel

The journey from a piece of metal to a precision-engineered component is a remarkable feat of manufacturing, made possible by the meticulous application of machining, grinding, superfinishing, and other finishing techniques. These processes, each contributing its unique advantages, work in concert to produce parts of exceptional accuracy and surface quality.

For machine shops looking to elevate their service offerings and compete in markets that demand the highest levels of precision or just experiencing a labor shortage and needing help catching up on backlog or meeting a deadline, outsourcing grinding and superfinishing emerges as a strategic option. This approach not only enhances your capabilities but also optimizes your resources, allowing you to focus on your core strengths while ensuring that every component you deliver meets the pinnacle of quality and performance standards. As the manufacturing landscape evolves, the ability to strategically partner with specialists will continue to be a differentiator for machine shops aiming for excellence in precision and customer satisfaction.

- Choosing a selection results in a full page refresh.

- Press the space key then arrow keys to make a selection.